Rubber conveyor belts are widely used in heavy-duty and continuous conveying operations. Their strength, abrasion resistance, and flexibility make them ideal for moving bulk materials across mining, cement, power, and port facilities.

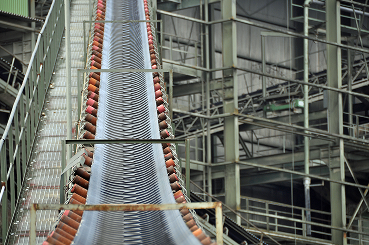

Transportation of ores, coal, aggregates, and minerals. Suitable for heavy loads, abrasive materials, and long-distance conveying.

Conveying sand, gravel, cement, limestone, grain, and fertilizers. Used in ports, power plants, steel mills, and storage facilities.

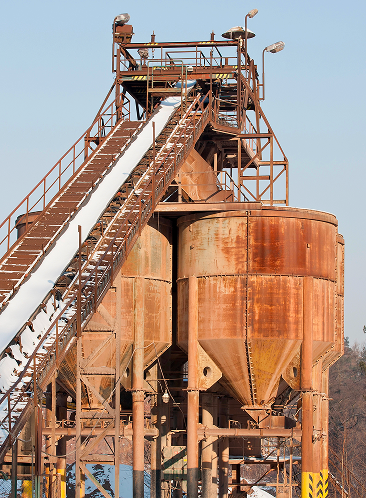

Raw material feeding (limestone, clay). Clinker and finished cement transport.

Coal handling systems in thermal power plants. Ash and slag conveying systems.

Transport of coke, sinter, iron ore, and scrap. Heat-resistant rubber belts used in high-temperature environments.

Handling of concrete, aggregates, and building materials. Mobile and stationary conveyor systems.

Conveying grains, seeds, feed, and biomass. Often combined with chevron or cleated belts for inclined conveying.

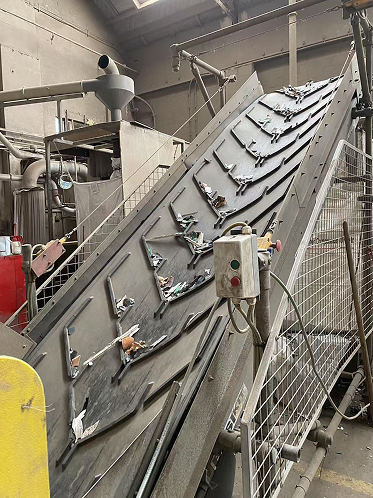

Transport of waste, scrap metal, glass, and recyclable materials. Oil-resistant and cut-resistant belts commonly used.

Conveying chemical products, fertilizers, and raw materials. Requires belts with chemical and oil resistance.

Loading and unloading bulk cargo such as coal, ore, and grain. Long-distance and high-capacity conveyor systems.