Product Introduction

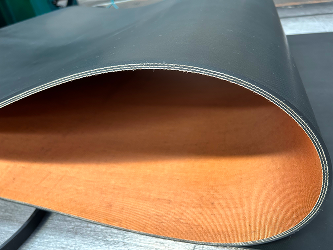

Dry-back Belt

You use a dry-back conveyor belt (fabric/raw back) when you need excellent grip for inclines or fragile items (like parcels, sacks) on slider beds, or in wood and sawmill industries where oils are present and a rubber-covered back would be unsuitable. It is essentially the belt's backside (non-carrying side) that is raw fabric, offering flexibility and grip on idlers, ideal for dry, demanding conditions.

Key Situations to Use a Dry-back Belt

Inclined Conveying:For fragile items (boxes, parcels, paper sacks) needing maximum friction to prevent slippage up slopes.

Slider Bed Conveyors:Where the belt slides directly on a solid surface, requiring a flexible, non-rubberized back.

Oily material conveying:To prevent rubber from degrading due to contact with oil. For example, in the timber and sawmill industry, this belt is used for conveying oily wood products.

Harsh Environments:Where a rubber-covered back might fail due to chemicals or extreme temperatures.

PACKWOOD offers dry-backed conveyor belts of various thicknesses in full rubber grade, ranging from 300mm to 1800mm in width and with cut edges.