Steel Cord Belt

For long distance

high-volume material transport

in tough environments

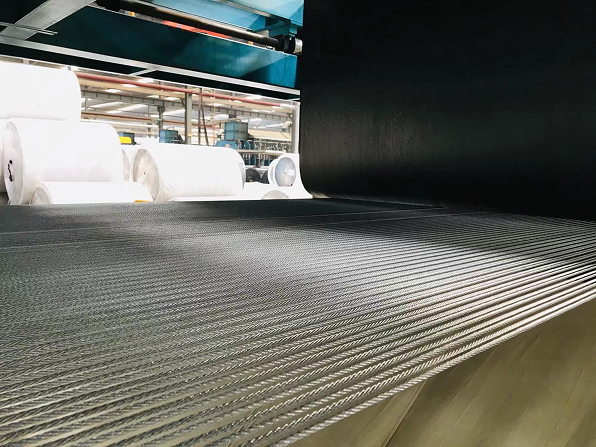

A steel cord conveyor belt is a heavy-duty belt with internal, zinc-galvanized steel cords for extreme tensile strength, designed for long-distance, high-volume material transport in tough environments like mining and ports. These belts offer superior impact resistance, low elongation, and excellent adhesion between cords and protective rubber covers, ensuring durability and efficiency in demanding applications where standard belts fail/are powerless.

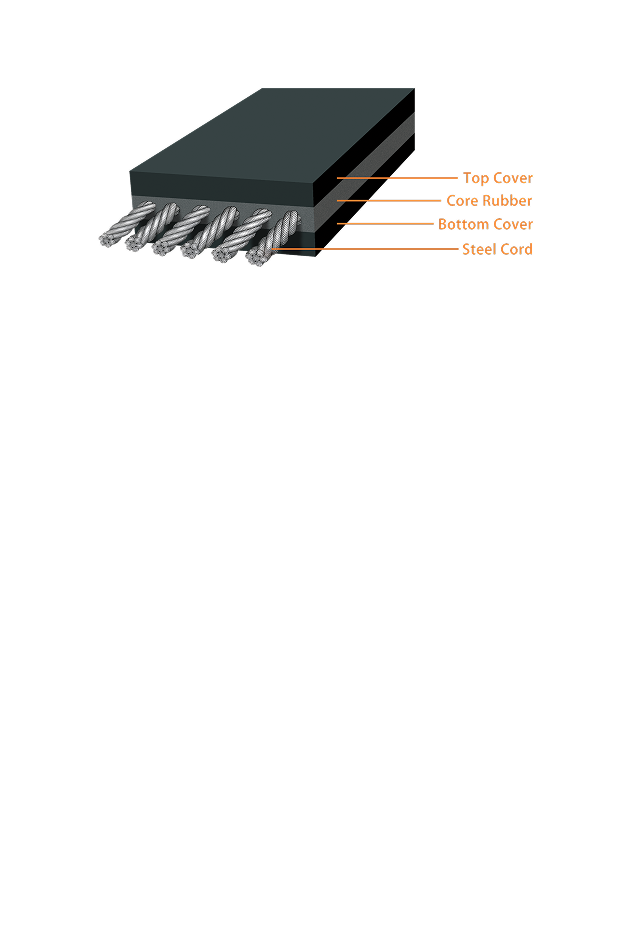

Key Components & Features

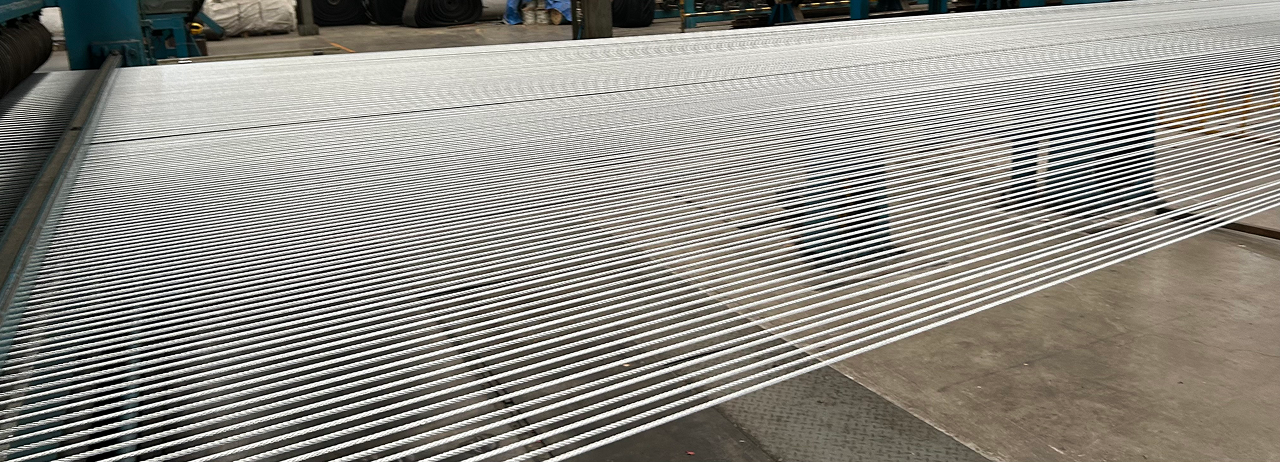

Steel Cords:

Zinc-coated steel cords provide maximum solidity and flexibility, with multiple threads for strength and corrosion protection.

Insulation Gum:

Encapsulates each steel cord filament, reducing friction and ensuring strong adhesion to the rubber covers.

Top & Bottom Covers:

Specially formulated rubber compounds offer varying levels of abrasion, cut, and flame resistance (e.g., DIN W, X, Y, K Grades).

Low Elongation:

Allows for efficient material transfer over long distances with minimal stretching.

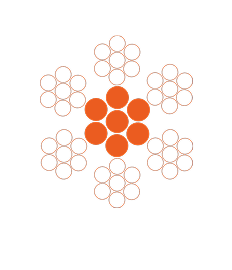

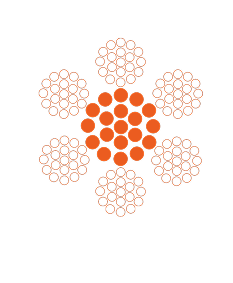

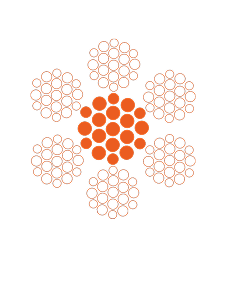

Steel Cord Structure

K6×7+IWS

K6×19+IWS

K6×19W+IWS

Applications

Mining: Transporting raw materials (coal, minerals, ore).

Quarries & Aggregates: Moving bulk materials from excavators to discharge points.

Ports & Transshipment: Handling large volumes of cargo.

Power Plants: Conveying fuel.

Steel Industry: Moving materials in demanding conditions.

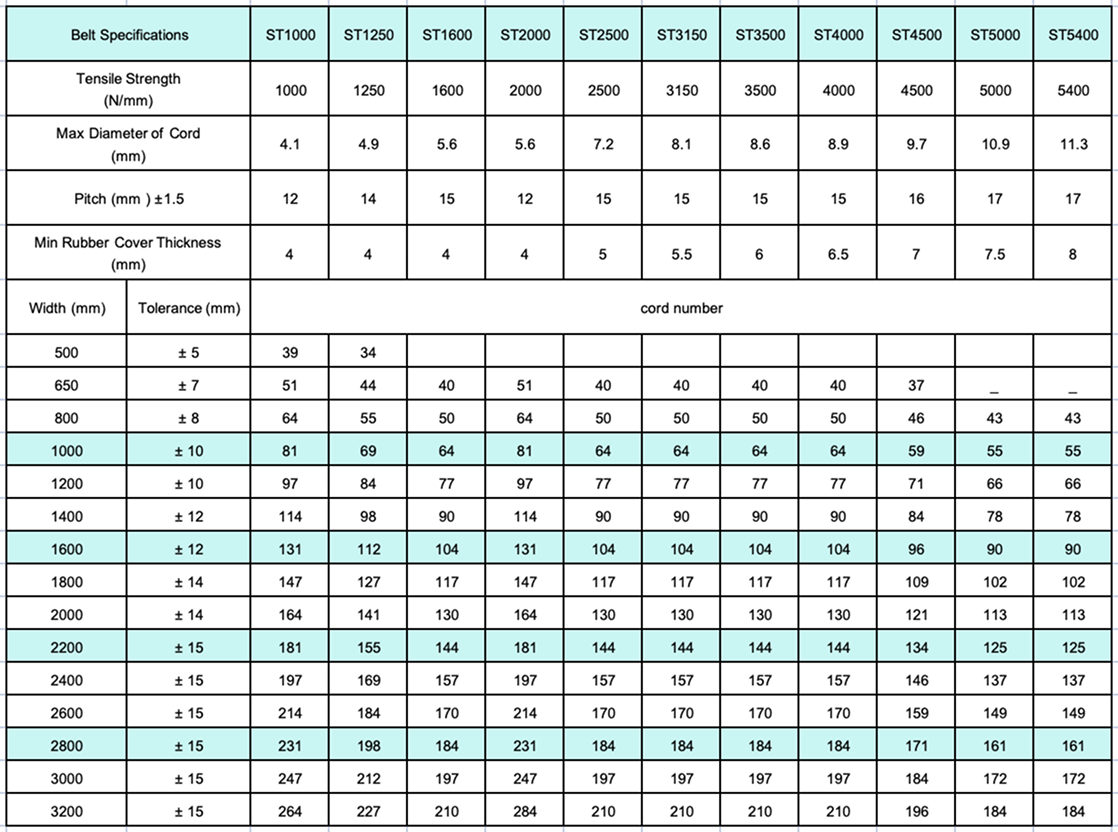

Technical Parameters

Benefits

High Strength:

Handles heavy loads and long distances.

Durability:

Exceptional wear and impact resistance.

Efficiency:

Lower cost/per-ton due to longer life and fewer splices.

Versatility:

Available in various cover grades and strengths (e.g., ST 800 to ST 4000).