Product Introduction

Rip-Stop Belt

In harsh material handling environments such as recycling, mining, and aggregate handling, sharp materials (such as rebar and concrete) can damage conveyor belts. Heavy-duty conveyor belts were developed to address this issue.

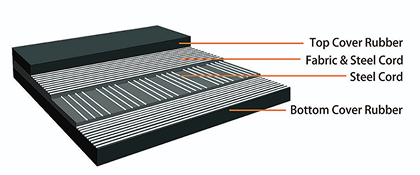

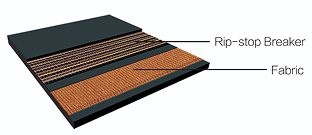

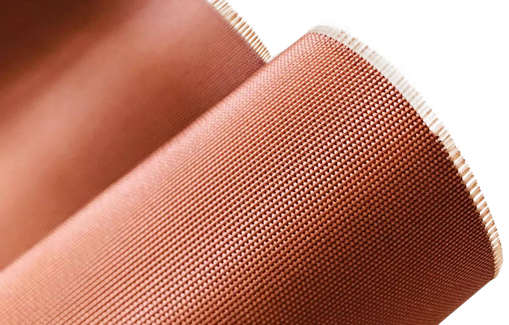

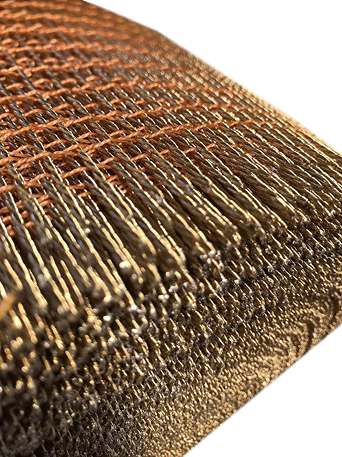

Featuring a carcass (layers) reinforced with steel wire or high-strength synthetic fibers to prevent longitudinal tears and punctures.

This enhances the belt's cut and tear resistance, extends its service life, and provides superior protection compared to standard belts. Its rip-stop mesh disperses impact energy and provides excellent fastener holding. Compared to some other belt types, steel breaker layers can provide a better troughing, preventing material spillage and increasing transport capacity.

Common Applications

Benefits