Product Introduction

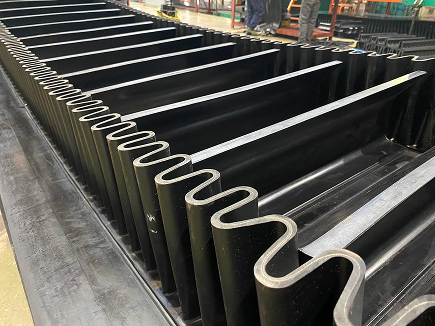

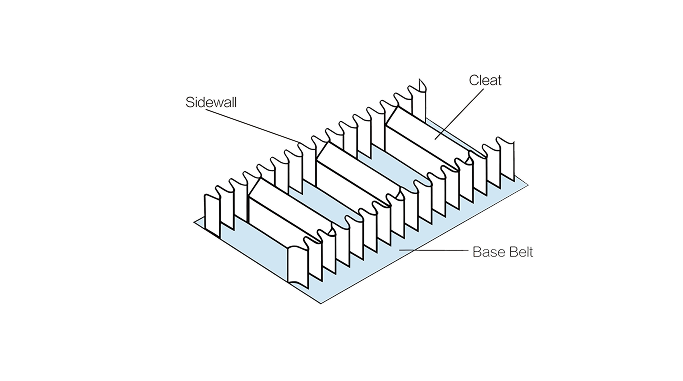

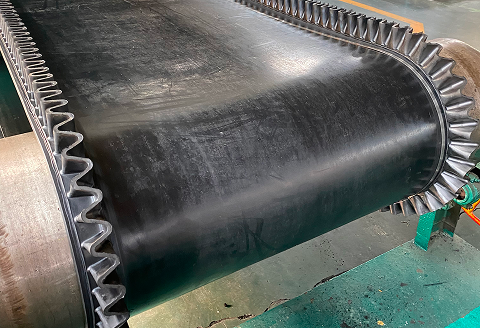

Sidewall Belt

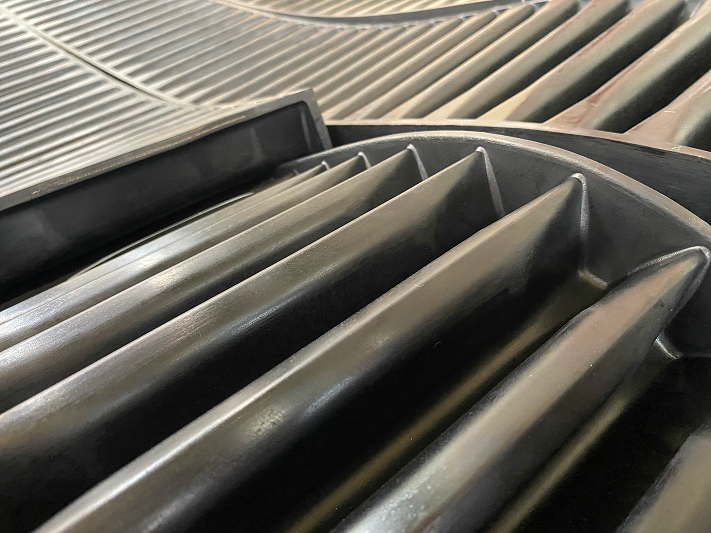

Sidewall conveyor belts are a primary solution for bulk materials conveying on steep incline and vertical.

The process of applying sidewalls and cleats to the base belt makes inclined conveying safe and reliable.

Our sidewall belt products are manufactured using the reliable hot vulcanization process. Even during high-temperature material conveying or under high-temperature ambient environments, there is virtually no risk of profile separation.

The sidewalls can be optionally fitted with built-in reinforcing fabric to increase their strength to resist material compression and impact.

According to application requirements, a full range of rubber qualities are available for sidewall belt (including the base belt and sidewalls). All products are produced according to internationally recognized standards.

CLEAT

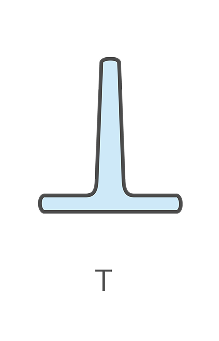

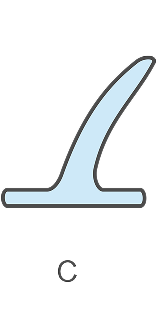

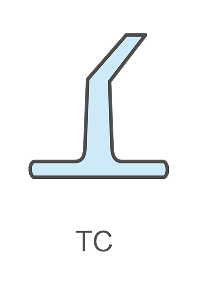

Three design styles are commonly used:

Straight "T",

Inclined "C"

Angled "TC"

The height range is as follows:

The cleats can be reinforced with fabric inside as needed.

Screw-reinforcement

as standard between

the cleat and

the sidewall.

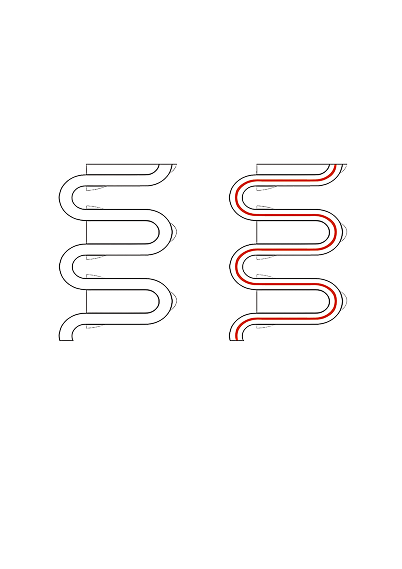

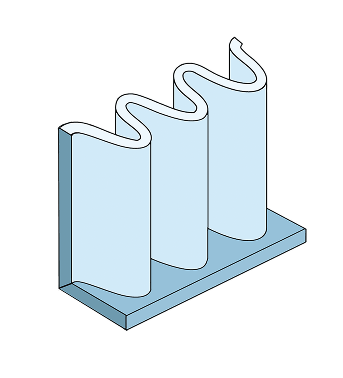

SIDEWALL

According to the shape, corrugated sidewall are divided into S, W and WM.

Dimensions are as follows:

Height:

S:40-630mm

W:60mm, 80mm, 120mm

WM: 120-240mm

Width:

25-75mm

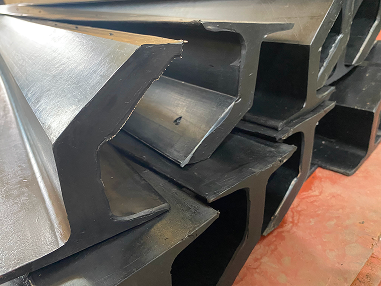

PACKAGING

For heavy-duty belts like sidewall belts, PACKWOOD’s custom-made crates (often metal or wood) protect the entire belt body, preventing crushing or bending, especially for belts used on steep inclines.

Protects sidewalls and cleats from being torn or bent.

Avoids permanent creases or distortions on the belt body that could affect performance.

It is crucial to avoid belt distortion, which can cause operational problems.